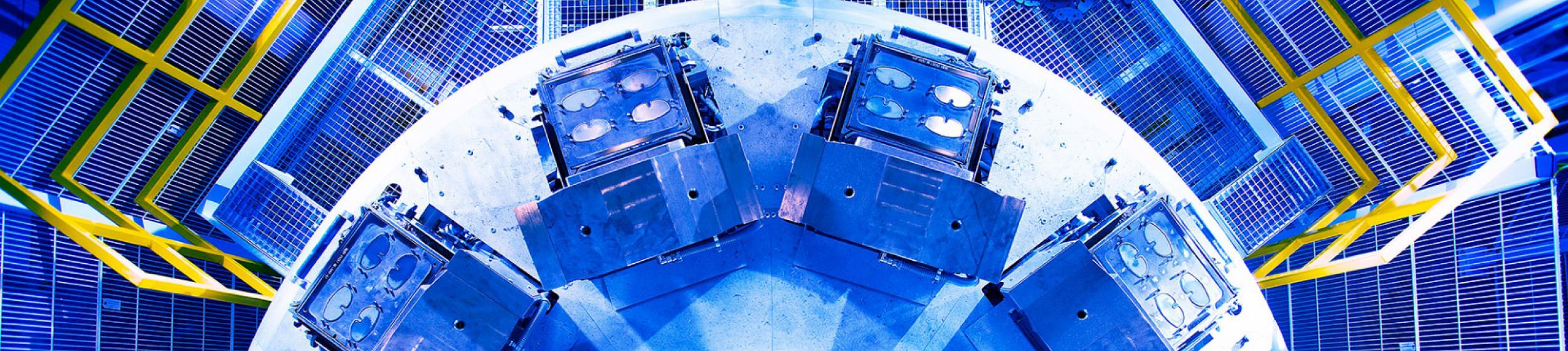

Mould - pressing tool

The mould is the main part of the pressing tool. The pressing tool generally consists of the mould, the ram (pressing punch) and the upper tool.

The upper tool is also called the mirror plate. The mould is usually made from a high-alloy tool steel. On its surface there are centring elements to hold the carrier plate

The contour of the friction lining to be pressed is worked into the mould. To facilitate removal of the lining from the mould, this contour is conical in the upper area (the so-called mould slopedraft).

Depending on customer requirements, IAG delivers project-specific press lines with agreed mold sizes for corresponding tool families. The IAG systems include the automatic filling of the pressing tool with the pressing powder, the distribution of the powder in the tool, the application of release agent and the cleaning of residues from the tool.