Pressing technology

Pressing technology in powder metallurgy

Pressing technology is an integral part of powder metallurgy, a manufacturing process that uses metal powder to create components. During pressing, the powder particles are compacted under high pressure to achieve the desired shape. This process enables the production of precise and complex components with bespoke material properties.

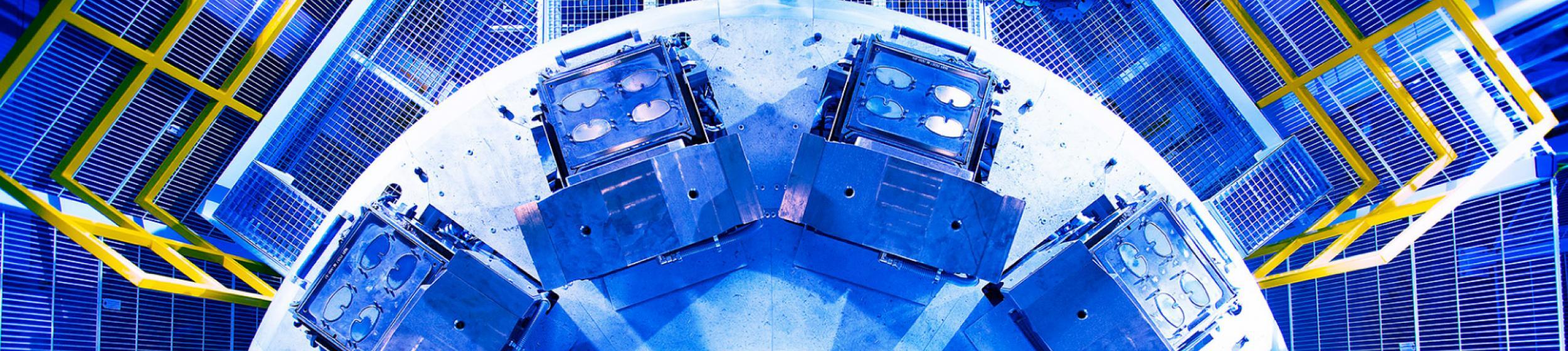

Various stamping processes are used in powder metallurgy. Uniaxial pressing is a common technique in which powder is put into a mold and pressed under pressure. In isostatic pressing, powders are uniformly compressed in all directions under high pressure in a closed chamber. Injection molding, on the other hand, involves injecting powder into a liquid binder matrix, which is then cured into the desired shape.

Press technology has many advantages. This enables the production of parts with high precision, complex geometries and tight tolerances. Different densities and porosities can be achieved by varying the pressure and geometry. In addition, pressing technology allows the use of various metal powders and the formation of composites.

Powder metallurgy and pressing technology are used in every field. The automotive industry uses powder metallurgy parts for engine, transmission and suspension components. In the aerospace industry it is used for structural components, turbine blades and braking systems. In the field of medical technology, powder metallurgy components are used for implants, instruments and medical devices. Tool manufacturing also benefits from powder metallurgy, such as the manufacture of cemented carbide tools.

Combining powder metallurgy with other manufacturing processes opens up new possibilities. For example, additive manufacturing (3D printing) can be combined with stamping technology to produce complex parts with enhanced material properties. This gives you even more design freedom to optimize component properties.

Overall, stamping technology plays an important role in powder metallurgy as it serves as the basis for the production of high-quality customized components. The continuous development of press technology and its integration with other manufacturing processes contributes to innovation and efficiency gains in various industries.