Strategic partnership between IAG and LF

Suitable system for mass production with the LIQFRIC® process

LF and IAG are developing a plant concept based on the LIQFRIC® friction pad technology and are also adapting the process for existing high-volume production plants.

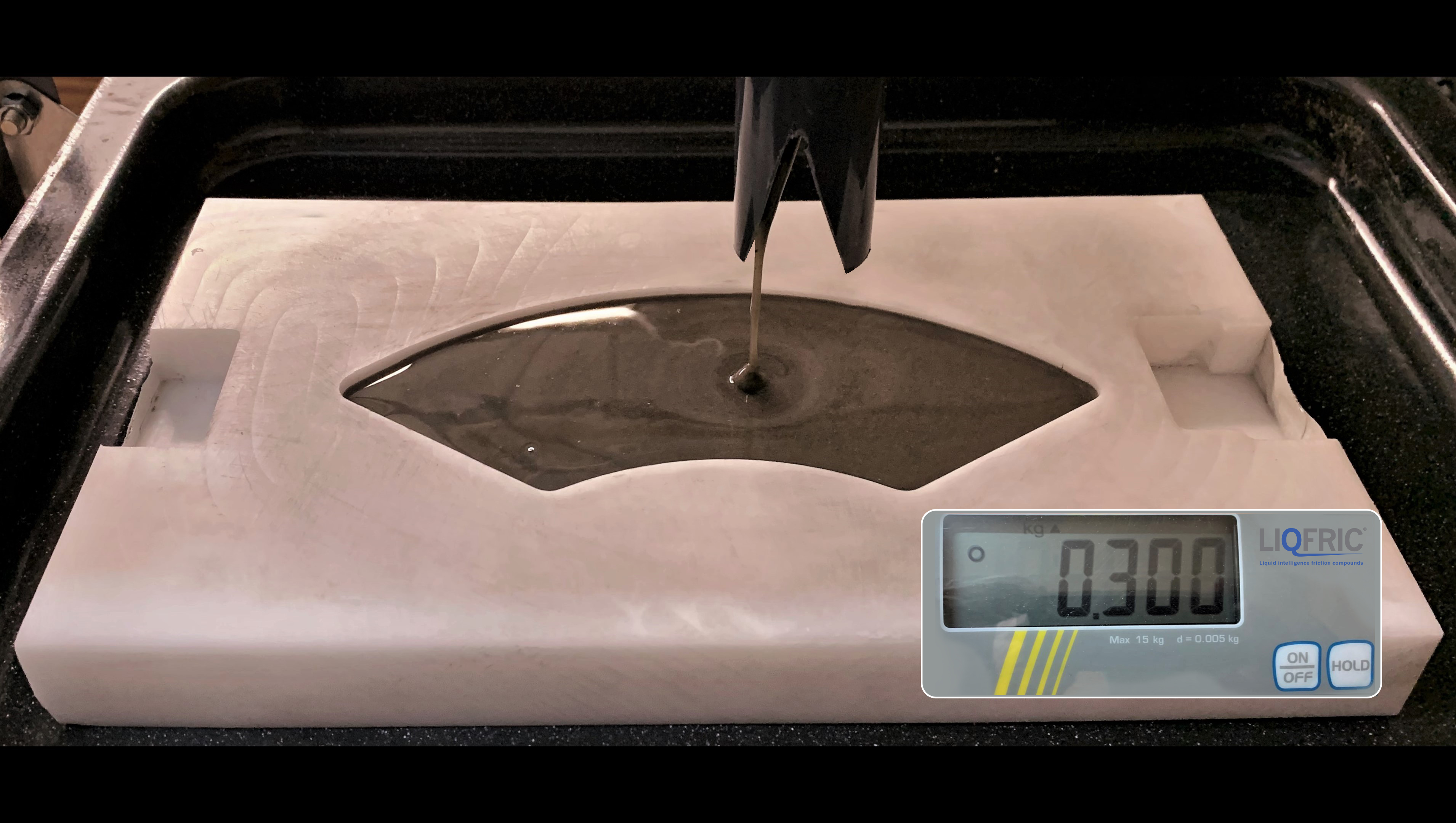

LIQFRIC® semi-automate mold filling.

Smart Friction Factory – the first series-compatible machine for the casting of friction linings at LIQFRIC®

“We are very excited to announce our collaboration with IAG (IAG Industrie Automatisierungsgesellschaft m.b.H), a well-known special machine manufacturer for the friction lining industry, with whom we can realize the next steps in the industrialization of our LIQFRIC® concept“, said R&D director Dr. Roman Milczarek.

In order to overcome the technical challenges, LF has signed a cooperation agreement with the Austrian IAG, with the intention of developing and building a large series plant based on the LIQFRIC® casting process in the near future. The aim is to achieve the proven CO2 saving targets of up to 85%, compared to the standard production conditions, which among other things would lead to a significantly more sustainable production of brake linings.

“For IAG, the goal is to develop a machine concept suitable for the mass market, and thus to lay the foundation for the industrialization of the LIQFRIC® technology.”, said managing director Stefan Gruber.

The cooperation was further expanded in order to adapt the LIQFRIC® material concept for the press systems currently in use in the friction lining industry worldwide. LF hopes that this will result in faster acceptance of this technology in the brake world, while simultaneously reducing production-relevant CO2 output. The CO2 saving effect in this case is significantly lower than with the original LIQFRIC® process, but still means a reduction of approx. 10-15% compared to the classic pressing process. The benefit lies mainly in the use of the already installed press- and plant capacities.

“With our project partners in the automotive- and automotive supplier industry and our learning curve from our Smart Friction Factory, we want to consistently go into series applications. Hereby we are realizing the next scaling step on the way to industrial use.", said R. Milczarek and added: “With our technological lead, we also want to advance the production of high-tech brake pads for electromobility and at the same time reduce fine particle emissions. As a strategic goal, we intend large-scale production in 2023. That is why we must take the right action now.“

LF GmbH & Co. KG was founded in Germany in March 2016 and follows the strategic idea of producing friction materials based on a liquid friction compound that can be hardened at room temperature (or faster at higher temperatures) to make high-temperature stable friction lining materials for automotive, rail, and clutch- as well as industrial applications. The company has entered into development projects and collaborations with some key players in the brake- and clutch industry in Europe and especially in Germany. LIQFRIC® is a registered trademark of LF GmbH & Co. KG.

IAG Industrie Automatisierungsgesellschaft m.b.H. was founded in Austria in 1986 and has achieved technological leadership in the development and production of fully automatic and individual special-purpose machines for the friction lining industry.

For further information, please visit www.liqfric.com

Tool filled with LIQFRIC® friction material

LIQFRIC® brake linings, which was produced on an already installed high-volume machine using the CO2 reduction process.

The success story of IAG and LIQFRIC

LF GmbH & Co. KG is a company founded in Leverkusen with the first development goal of developing, producing and marketing innovative friction materials for the application area of brake linings and clutches and initially reducing the thermal energy input required for this by up to 85%.

For further information please visit www.liqfric.com