Adhesive coating on brake pads

An adhesive coating on brake pads is essential for securely holding the friction material onto the backing plate, ensuring reliable brake performance. The adhesive coating creates a strong bond between the pad material and the backing plate, preventing detachment or shifting during braking.

The quality of the adhesive coating is checked during the manufacturing process. Visual inspection and mechanical tests are conducted to assess the coating. Attention is given to uniform coverage, avoiding any delamination, cracks, or irregularities. The adhesive coating should be complete, without voids or air pockets. It also needs to be heat-resistant to withstand the high temperatures generated during braking.

A high-quality adhesive coating is crucial for safe and reliable brake performance. Through careful inspection and control during manufacturing, potential defects can be identified and addressed early on to ensure the quality and performance of the brake pads.

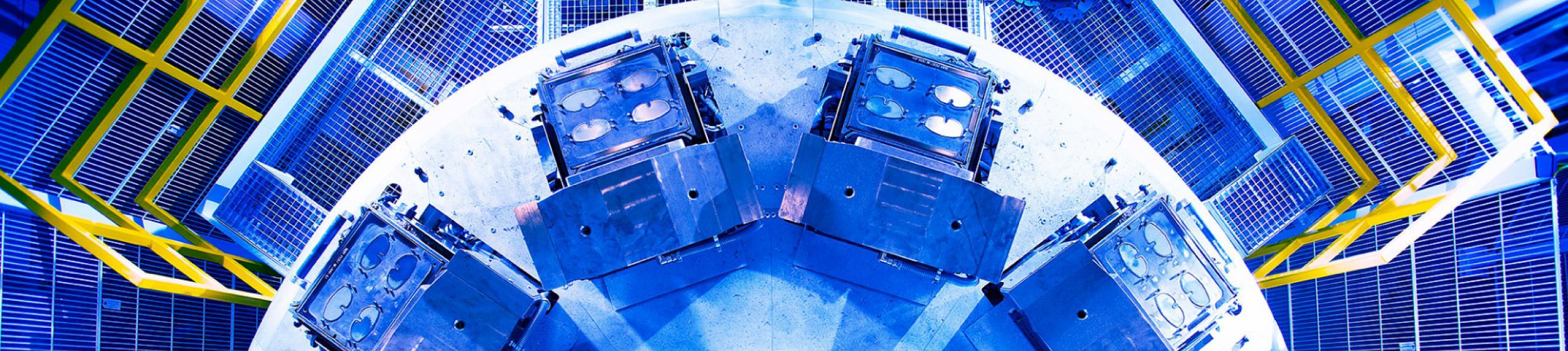

Depending on the customer project, IAG systems check the correct application of the adhesive layer using a camera system or an RGB sensor.