Hydraulic presses

Hydraulic presses, also known as hydraulic presses, are powerful machine tools that use hydraulic energy to apply significant force to a workpiece.

A hydraulic press consists of a hydraulic cylinder filled with oil and a piston rod that moves within the cylinder. By applying pressure to the oil, the piston is pushed down and a large force is transmitted to the workpiece. This allows you to machine materials such as metals, plastics, rubbers and even composites.

Hydraulic presses have many advantages. The ability to generate large forces allows for precise control of pressure and even distribution of forces on the workpiece. Hydraulic technology also enables variable speed control to adapt to different materials and requirements.

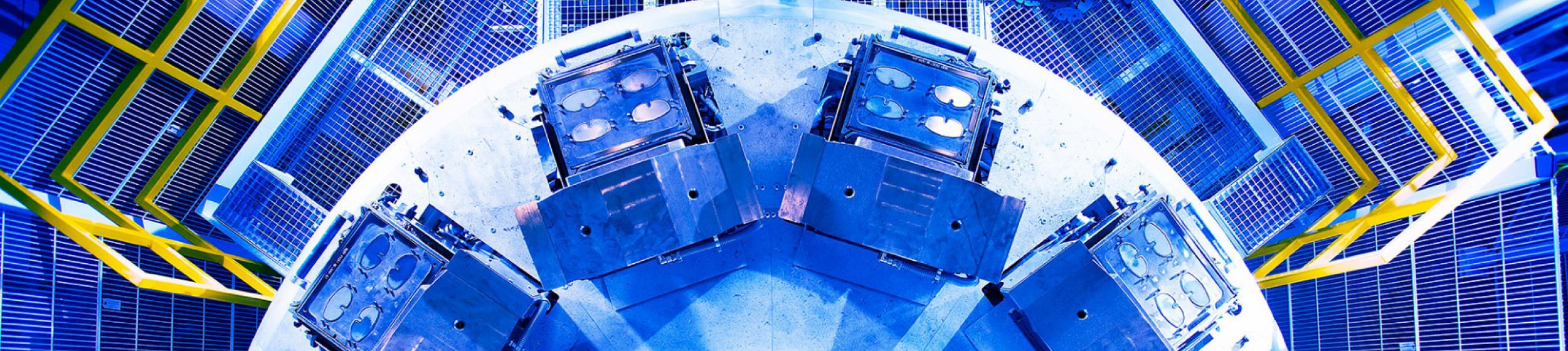

IAG offers a wide range of presses for different applications, from small bench presses to large industrial presses with capacities of several tons. IAG hydraulic presses are project-specific systems that are characterized by high precision, reliability and performance, contributing to increased productivity and quality in many sectors of industry.

Overall, hydraulic presses are essential tools for many manufacturing processes. They provide efficient and cost-effective solutions for material conversion and play an important role in modern industry.