Brake pad

The brake pad is located between the back plate (backing plate) and the rotating element (brake disc or drum). During the braking process, the brake lining (friction lining) is pressed mechanically or hydraulically against the (usually) metallic friction surface. A modern brake pad has a multi-layer structure (backing plate, "underlayer" and composite friction material).

A brake pad must have the following properties:

- constant coefficient of friction

- temperature stable

- mechanically resilient

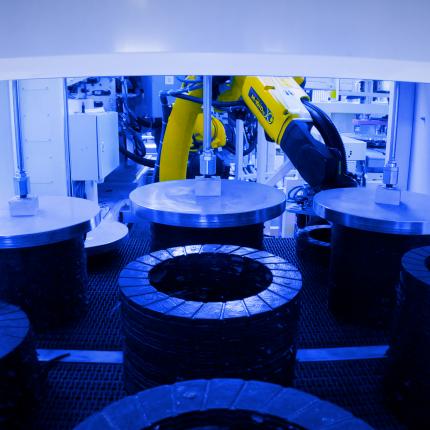

The IAG systems ensure the smooth production process in a fully automatic state, produce coverings from powder to polymerized coverings

Clutch lining

Clutch linings are friction linings that transmit power by force. These linings are tailored to the application and essentially consist of a carrier material and the friction lining. In the past, the linings were riveted to the carrier material, today the two components are glued together.

The IAG company has supplied systems for the process from powder to pressed clutch on the clutch carrier, or fully automatic machines for the production of so-called windings

Friction lining

Friction lining is the pressed part on the carrier plate/back plate. This consists of friction material. The task of the friction lining is to generate a braking force via friction.