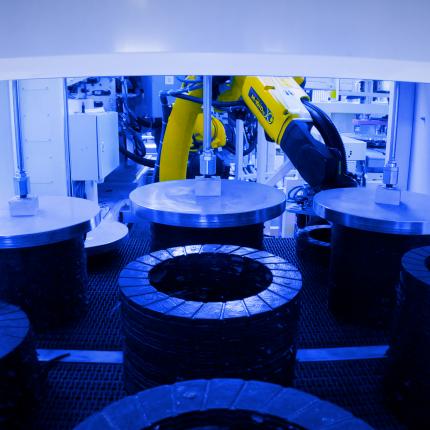

Brake Pad Press

A brake pad press is used in the production of brake pads and forms a central part of modern brake pad manufacturing equipment.

The brake pad is located between the backing plate and the rotating element (brake disc or brake drum). During the braking process, the brake lining (friction lining) is pressed mechanically or hydraulically against the (usually) metallic friction surface.

Modern brake pads have a multi-layer structure consisting of a backing plate, an underlayer and a composite friction material.

To ensure reliable performance, a brake pad must have the following properties:

- constant coefficient of friction

- temperature stability

- mechanical resilience

In a brake pad production line, the brake pad press is typically designed as a powder press, where the friction material is compacted from powder form into the final shape before polymerization.

IAG systems ensure a smooth and fully automated production process, producing brake pads from powder to fully polymerized friction linings. These systems are supplied as turn-key solutions and can be integrated into complete brake pad production lines.

Similar applications:

Clutch lining

Clutch linings are friction linings that transmit power by force. They are tailored to the application and essentially consist of a carrier material and a friction lining. In the past, clutch linings were riveted to the carrier material; today, the two components are bonded together.

IAG has supplied systems covering the process from powder to pressed clutch linings on the clutch carrier, as well as fully automatic machines for the production of so-called windings, delivered as turn-key manufacturing equipment.

Friction lining

The friction lining is the pressed component on the carrier plate or backing plate and consists of friction material. Its function is to generate braking force or torque transmission through friction.