Flexible production lines for clutch linings

Locally made special-purpose machines for the international automotive sector

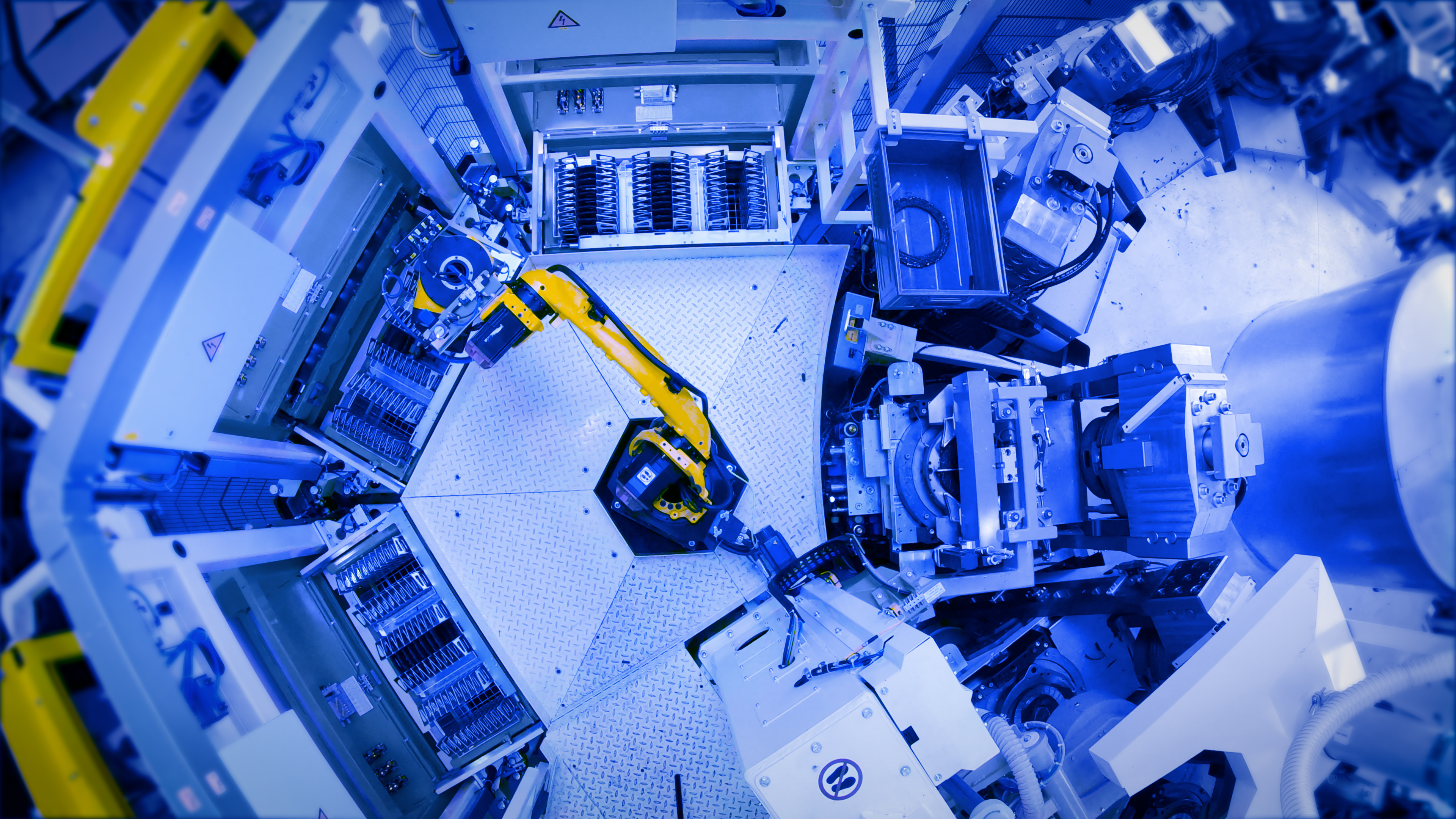

IAG Industrie Automatisierungsgesellschaft m.b.H. has just added to its growing list of success stories. A renowned, global group for system solutions in the field of passenger car and commercial vehicle mobility decided to take advantage of IAG’s decades of experience when it placed its order with the company. Together with the client, a fully interlinked system was developed for manufacturing clutch linings for the automotive sector. With the client’s specific requirements implemented and the various processing stations now interlinked, this individual production line joins the ranks of some of IAG’s most complex, highly automated productions

Peter Unger, Head of R&D at IAG said, “The international trend towards automation is not slowing down. Systems by IAG are state-of-the-art and developed with the highest level of precision - our competitive position can only be upheld with the “Made in Europe” label.”

Production line with a wide range of uses

The assignment was to come up with a highly flexible machine that is able to manufacture three different products simultaneously on a rotary table, meaning production is faster, more efficiently and more economically than conventional friction lining presses. The development and interlinking of the following work stations is a further special feature of the system.

- Rotary transfer machine with 12 presses with additional features according to the client’s specific requirements

- Magazine for storing the windings

- Robot with special gripper for placing the windings into the press

- Robot for removing the compacted parts and transferring to the deburring station

- Deburring station

- Robot with vacuum gripper for removing from the deburring station and transferring to the tensioning stations

- Tensioning stations with a shared conveyor belt

- Brushing and spraying station for cleaning the pressing tools with a specially produced brush

Quality characteristics of the IAG press

Over 40 years of experience in complex special-purpose machinery were channelled into the design, development and construction of this production line. With our know-how, we were able to implement and even optimise the client’s particular requirements to a high standard in order to present the client with a highly flexible machine with a smooth, fully automatic process.

“IAG is a trustworthy and high-quality provider of pressing machines for the production of brake and clutch linings. The high quality, the professional standard for the development of the press and the reliability in the implementation greatly impressed us”, said the Head of Clutch Facings Production.