Expert talk: The IAG and Brake Academy on hypes and trends in special purpose machinery

IAG founder Olaf Pokorny on the history of IAG - and the future

Mohammad: Hello, everyone. Today is February 10, 2022. Thank you for joining us today. I'm Mohammad Vakili, the founder of Brake Academy: A global educational platform focused on bringing knowledge to engineering professionals in the mobility field. Today we are hosting an industry icons chat where up-and-coming professionals can learn firsthand from the experiences of experts in the field. My guest today is Olaf Pokorny of IAG from Weikersdorf, Austria. Olaf, thank you for joining us from Austria.

Olaf: Thank you. It's a pleasure.

Mohammad: Welcome to the program. If I didn’t pronounce the name of the city right, correct me.

Olaf: It was quite good.

Mohammad: Great. So, let's talk about the pandemic. How are you affected by it personally and as a company?

Olaf: Personally, I have been vaccinated three time, so I feel more or less safe from getting the serious illness. And I have reduced my social activities a little bit to stay on the safe side. In the company, until now we have been relatively lucky and only had a few cases and we haven’t really had any disruptions from it. And we try to keep people safe as much as possible and to get them tested two times a week and if some someone is infected, then they're quarantined and there's no chance for them to infect their colleagues and so on. So, we do what we can.

Mohammad: Is the country still under lockdown?

Olaf: No, there's no lockdown at the moment. There are some restrictions: We have to wear masks when we meet people and, in the restaurants, they check whether everybody coming in is vaccinated or safe. So, we’ve already got used to it

Mohammad: So, they require a vaccine passport at a restaurant, right?

Olaf: Yes, they need to see the vaccine passport.

Mohammad: I first learned about the IAG in the 1990s when I was deeply involved in the world of friction. Tell us how IAG started and in what year.

Olaf: IAG was established in February 1986 by me and my two partners Fritz Breier and Ernst Brunner. The three of us were employees in a company making all the special-purpose machinery and presses. Unfortunately, this company went bankrupt, not because of our products - it was a management problem. And so, we lost our jobs. I was thinking about what to do when, finally, I had the idea to start my own business. And I convinced my two colleagues to start the business with me. We started off quite poor in a little rented office and we had a lot of new ideas and were optimistic and ready to work hard. But we started with just three drawing machines in a little office with no money. So, it was quite an interesting time.

Mohammad: So, you basically started all over again, this time from zero that time?

Olaf: We started from zero. Even a bit below zero.

Mohammad: Below zero, even.

Olaf: Yeah.

Mohammad: So, when did you start getting into the day-to-day operation of IAG?

Olaf: It started when we established the company working in IAG. I was present in IAG from the from the first day on.

Mohammad: And what was the first piece of machinery built by IAG and for what purpose?

Olaf: When we started, we only got very small projects to design something, to repair something… it was difficult with the business. The first machine we built was a special-purpose machine far removed from the friction material business. It was a machine inserting ignition caps in metal carriers, with a high frequency and very high precision. We built it for a company not far from us. It was the first project. And we built the first laboratory press in 1987. And the first Rotary machine, I think, was in 1988.

Mohammad: The laboratory press you are referring to was for friction purposes?

Olaf: The laboratory process was for friction. It was a newly designed press system. And we put the new ideas we had into this press. We built it for a customer who wanted to test us to see if we could build such machines. But we were successful. It was the first step in the friction material business. And from that moment, it began to work.

Mohammad: And today you make all sorts of machinery for friction industries?

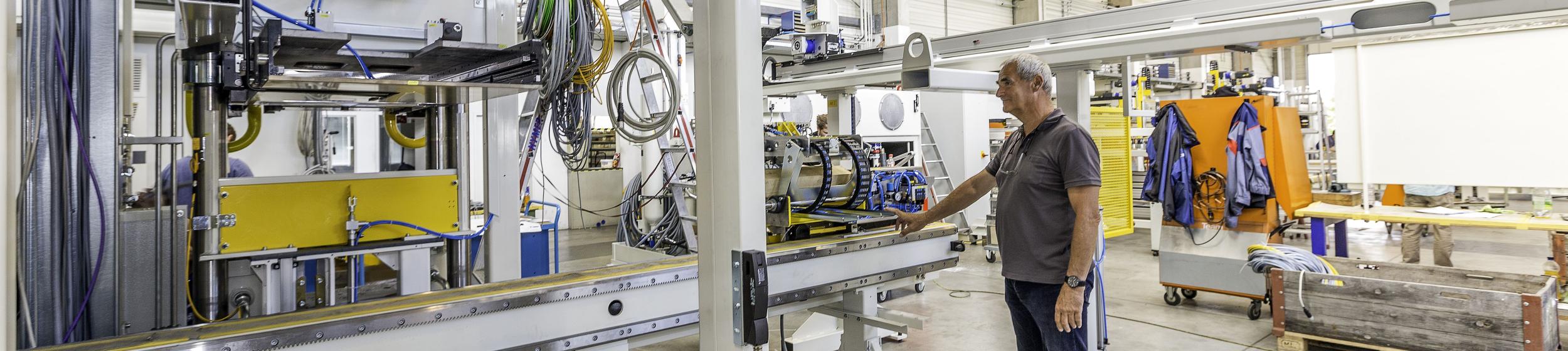

Olaf: Yes, it's mainly our core business. But besides that, we are also manufacturers of special purpose machinery from time to time. If we are too busy with the friction business, we make special-purpose machines for Austrian Industries.

Mohammad: Are there any particular industries you build equipment for other than friction industries?

Olaf: Nothing special. We built some machines for a company involved in making frame systems for the building industry. One customer needed a line to produce filter housings for fuel filters for the automotive industry. So, we have done many different things: A production machine, a sampling machine for ski bindings, for example.

Mohammad: So, IAG doesn’t just build equipment for friction industries.

Olaf: We have a lot of know-how in the automation business, so we use that for other projects too.

Mohammad: One of the features of your equipment, even for friction industries, is automation.

Olaf: Yeah. We have a lot of knowledge in automation processes, industrial processes.

Mohammad: One feature that the IAG Company offers to the customer is remote customer assistance. Did that come about because of the pandemic, or it was it always there?

Olaf: No, no. That has been state of the art for many years for us. We assist our customers with remote service. It saves a lot of maintenance costs for the customers. They have problems and call us, and we help them with running the machine and can tell them what the problem is and how to solve it. We solve software problems or there are issues which we solve from our office here. So it's very efficient for all of us.

Mohammad: So, there’s no need to travel.

Olaf: Yeah, exactly. Especially in times like these. With the pandemic, traveling is difficult anyway. So now it's quite a lot more helpful than before.

Mohammad: I hear that no customer of IAG only has one of your machines. What does that mean?

Olaf: I would say that we also have some customers who just have one machine. Relatively small manufacturers of each material. Most of them have several machines and some have up to 100 of our machines. So, in total, till now we've made around 500 machines for the friction business. And I think two big customers have more than a hundred.

Mohammad: So once a customer can buy a machine, it's not the end of it. They keep on buying more equipment because they like what it does.

Olaf: Yes, I think our customers are satisfied and they are convinced about the machines. If they need to increase their capacity, they also increase the number of machines.

Mohammad: I understand. Does IAG have branches or subsidiaries outside of Austria?

Olaf: No, we don't. We have some agents who work for us. But not only for us.

Mohammad: Nowadays you hear a lot about electric vehicles and autonomous vehicles.

Olaf: Yeah.

Mohammad: Are you involved in that? If so, in what way?

Olaf: What we actually do, probably more for electric vehicles, is we develop production equipment to produce bipolarplates for fuel cells. We see it as a chance for us to open a new business.

Mohammad: That's great. So, you're moving on with the technology?

Olaf: Yeah. We are always open for new ideas and new projects. And we are also thinking about the diversification of our company.

Mohammad: Of course. I know IAG is a very complicated company to operate and run. But aside from that, are you involved in any other activities in the industry?

Olaf: Yeah, we are.

Mohammad: What kind of activities are you involved in?

Olaf: We develop, as I said, this production process for bipolarplates for fuel cells and a part of our companies working for gas diagnosing systems which are used in testing for motors. Things like that.

Mohammad: Yes. And you're still active nowadays in the company, is that correct? What role do you play now?

Olaf: Officially, I retired last year. But most of the time I am present in the company and on the advisory board. And I still work as a consultant for my company. And if my people need me, I am available anytime.

Mohammad: That's great. Even though you're retired, you spend most of your time back in the company.

Olaf: Yeah, of course. I like it. It's my baby.

Mohammad: That's great. How do you plan your time and activities?

Olaf: I also have some hobbies which I like, and now I spend a little bit more time on them. I go flying and skiing and swimming and sailing…

Mohammad: You fly a plane yourself?

Olaf: Yes. I fly airplanes, fixed wing planes, helicopters, gliders… So that's my biggest hobby - flying. I fly quite a lot.

Mohammad: Quite a selection of hobbies.

Olaf: I do a lot of sport to keep my body fit.

Mohammad: What you consider your biggest achievement?

Olaf: The biggest achievement I am proud of is my company being the leading manufacturer of presses for the friction material in the industry. And that we deliver our machines to every continent. I think that’s my biggest achievement.

Mohammad: I've been around the world in many friction companies and almost everywhere I've been, I've seen your equipment, so I can relate to that.

Olaf: It makes us really proud – we have delivered to every country except Antarctica.

Mohammad: If you had to do things all over again, what would you do anything differently?

Olaf: I am happy with how it went. And if I had to choose again, I think I would do the same and I would do it in the same way because we have been successful, and everything is fine for me. For sure, something can always be improved. But in general, we would do it in the same way again, I think.

Mohammad: That's good to know.

Olaf: Yeah. You know, I like my life. Anyway, I’m satisfied

Mohammad: What kind of books to read outside the technical stuff?

Olaf: Besides technical books, when I am free, when I have time to read a book, I look for something entertaining to relax.

Mohammad: Do you like fiction, stories, novels, stuff like that?

Olaf: Sometimes they are interesting, novels and different books.

Mohammad: That's nice.

Olaf: Different books, but mainly to have some entertainment.

Mohammad: That's great. We all need a bit of entertainment after a long day of work, don't we?

Olaf: It’s a really good way to relax and to get other opinions.

Mohammad: Well, thank you, Olaf, for taking time to chat with me

Olaf: It was a pleasure for me too, Mohammed. I enjoyed it.

Mohammad: A heartfelt thanks to our technical staff. Brake Academy will be bringing you more interviews with industry icons in the future to the Brake Academy global audience. We would like to hear from you. Please send us your feedback and questions to info@brakeacademy.org. From Austria, from Olaf Pokorny, and from New York City from Mohammad Vakili. Until next time.

Experttalk between IAG and Brake Academy

The founder of the Brake Academy, Mohammad Vakili, in conversation with IAG founder Olaf Pokorny on the history of the company, the challenges of the present and dreams of the future.