Fuel cell manufacturing

Fuel cell manufacturing, is an important aspect of the development and production of fuel cell technology. However, there are still some major components of fuel cells where there is a lack of industrialization.

Such component is the membrane electrode assembly (MEA), which is a critical component in the proton exchange membrane fuel cell. The MEA consists of a polymer electrolyte membrane, catalyst layers, and gas diffusion layers. The production of MEAs involves several complex and specialized processes, such as electrode coating, membrane lamination, and hot pressing, which require careful attention and control to ensure high-quality and consistent production.

Another major component that lacks industrialization is the bipolar plate. Bipolar plates are an essential component of fuel cells that serve as both an electrical conductor and a gas separator. Traditional bipolar plates are made of metal, but newer composite materials, such as graphite-polymer composites, offer advantages such as lighter weight and lower cost. However, the manufacturing of composite bipolar plates on a large scale still faces some challenges in terms of production efficiency and consistency.

Overall, the lack of industrialization in certain key components of fuel cell technology can pose challenges to the widespread adoption and commercialization of fuel cells. However, continued research and development, as well as collaboration between industry and government, can help to overcome these challenges and accelerate the industrialization of fuel cell technology.

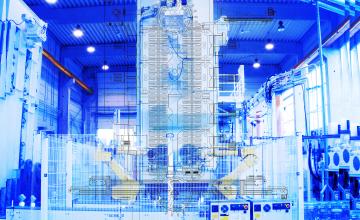

To enable the anticipated mass manufacturing of million units, IAG is developing solutions in collaboration with others. Customers are involved in the creation of the final solution through the use of development tools and a variety of material possibilities. Eventually, a machine capable of mass production will be introduced as a result of this method.