Manufacturing lines

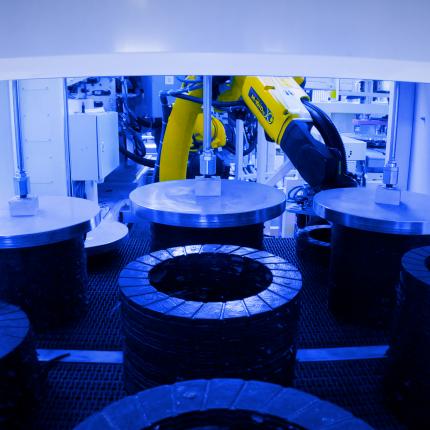

In a manufacturing line, the individual production steps are divided amongst various processes and machines that take place or are executed one after another. A so-called “material flow system” is used to connect the individual steps. If the material flow system is fully automated (without manual interventions), the term “fully interlinked” is used.

Since the individual manufacturing steps can present differences in their cycle times, buffers often need to be integrated in order to utilise the manufacturing lines to optimum capacity.

Thus the development of manufacturing lines involves not only the development of individual manufacturing steps but also a material flow system that transports the individual parts. To this end, the following steps are roughly necessary in the development phase, as they can interact with each other:

- Cycle time calculations must be carried out for all steps so as to determine the optimum combination, create duplicates of individual stations, and ensure sufficient dimensions for the material buffers.

- The transport of material must be simulated with a material flow analysis.

- A layout of the manufacturing line must be elaborated.

- Any additional feasibility studies should be carried out for the individual steps in advance. To some extent, prototypes must also be prepared for this purpose.

Depending on the degree of automation of the manufacturing line, individual employees may be required for the operation, or unmanned shifts may be possible.